Squeeze Casting Customized Aluminum Scooter Parts Spare Components OEM

Basic Info

| Model NO. | customized |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 1 |

| Certification | CE, RoHS, ISO 9001:2000 |

| Equipment | 200-1100t Casting Machine |

| Surface | Trimming, Deburring, Polishing, Shot Blasting |

| Type of Material | ADC12/A356/A380/A319/A380 |

| Process | Squeeze Casting / Hpdc |

| Advantage | High-Strength High Density |

| Description | Aluminum Die Casting |

| Transport Package | Carton |

| Specification | OEM |

| Trademark | CEX |

| Origin | Qingdao, China |

| HS Code | 7616991090 |

| Production Capacity | 1000tons/Month |

Product Description

We use squeeze casting to replace traditional die casting to improve the strength of the electric scooter parts, to meet the customer's special requirements for the strength of electric scooter, and to ensure the stability of the tent under large external forces.If you have similar needs, you can contact usWhy squeeze casting can improve the strength of the parts? Here is all you need to know :

Squeeze casting in CEX

CEX Casting is China Leading Squeeze Casting Company. With our self-developed squeeze casting equipments, our Squeeze Casting Service Helped Many Companies To Improve The Mechanical Properties Of Different Parts. Those Squeeze Cast Products Have Better Mechanical Characteristics Than Conventionally Cast Parts Because Of Their Higher Density, Finer Scale Of Grain And More Homogeneous Microstructure.

Multiple applications of CEX squeeze casting parts

Case 1 Parts need higher strength. Use Squeeze casting + T6 treatment to get 50% Strength Increase

Squeeze casting has the capability of producing near net shape castings that are essentiallypore free. This permits the solution heat treatment of the castings so that excellent mechanical properties can be attained.

Part Name: Folding parts for outdoor tentsMaterial: A356.2Heat Treatment: T6Strength 50% higher than traditional HPDC to give better support over longer distances.

Case 2 Parts need good surface texture to meet high resistance and air tightness requirements.

Squeeze die casting produces the minimum amount of air bubbles in the die cavity, that's why the metal parts have low porosity. The final products in squeeze casting have a good surface texture.

Part Name: Water Pump ConnectorMaterial: A319Heat Treatment : No NeedNo porosity pits, dents and scratches on entire surface.

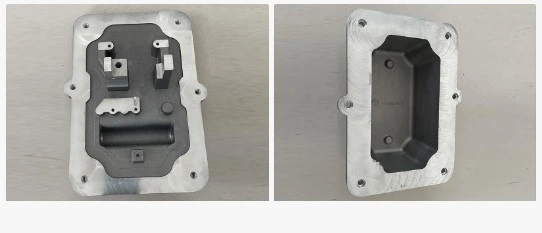

Case 3 Parts with complex structure. Use squeeze casting to reduce machining processing and save costs.

These parts with complex structures need several steps of machining after forging. Unlike forging, the squeeze casting process is capable of producing higher integrity components in one step. And good mechanical properties can be attained as well.

Part Name: Electric Scooter Folding PartMaterial: A356.2Heat treatment: T6Reduces machining process, saves at least 40% of the costs.

Other related products

Comprehensive capability in aluminum casting--more than squeeze casting

| Process | Aluminum Die casting, Squeeze casting+T6, Zinc Alloy die casting,CNC machining, Turning |

| Equipment | Cold chamber die casting machine:200T/280T/400T/600T/800T/1100T.CNC centers, CNC turning, CNC lathes, electrical pulse, line cutting, milling, drilling, grinding |

| Material | A319, A356, A360, A369, A380, A383, A384, A413, A535, 44300, 44300, 46000, AlSi9Mg, AlSi9Cu3, ADC12, ZL102, ZL104, ZL108, Zamak2,3,5,7 ect.Squeeze Casting: A356+T6, A356.2+T6, AlSi9Mg+T6, Zl108+T6, AlTi-Alloy+T6 |

| Surface | Trimming, Deburring,Polishing, Shot blasting, Sand blasting,Tumbling, Powder coating, Anodizing, Chrome, Zinc, Electrophoresis, Passivation, Chemical coating. |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Products Application | Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect. |

Squeeze Casting--Integrated the advantages of forging and Traditional die casting

160-ton to 1100-ton machines to produce different partsBy now, we have 4 squeeze casting machines ranging from 160-ton to 1100-ton. Our squeeze casting products covers automotive parts, medical devices parts, electrical enclosures/housings, lighting fixture parts, heat sinks, hardware tool parts, etc., with the weight ranging from 20G to 20KG.

20+ years mold development experience to ensure the mold quality

One of our strength is that we have experienced mold design engineers. Every step in the manufacturing of molds like designing, material selection, standard parts selection, heat treatment, machining and assembly is under strict control. Our mold engineers always keep in close touch with all customers to solve problems timely. High-quality molds can effectively ensure the quality of our products.Strict quality to guarantee product quality

ISO 9001Three-coordinate measuring instrumentHardness TesterX-Ray detector

Certifications

contact us now

Would you like to learn more about squeeze casting?Do you need to reduce the cost of forged parts?Do you need to improve the mechanical properties of your die castings?Are you looking for new suppliers to reduce purchasing costs and improve product quality?For anything you need to know about squeeze casting, contact us now! FAQ1. How can I get the quotation?

Please send us information for quote: drawing, material, weight, quantity and request.

2. If we don't have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 35-40days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time:20-25 days after the payment. The accurate time depends on your product.

5. What is your payment method?

50% deposit, balance 50% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..

Customized/OEM Lightweight High-Strength Aluminum Alloy Die Casting Process for Electric Scooter/Vehicles/Auto/Car/Part